Worker making a casting mould using sand, 1925

Factory to Farm: Making Agricultural Implements in Australia, about 1925. National Film and Sound Archive of Australia

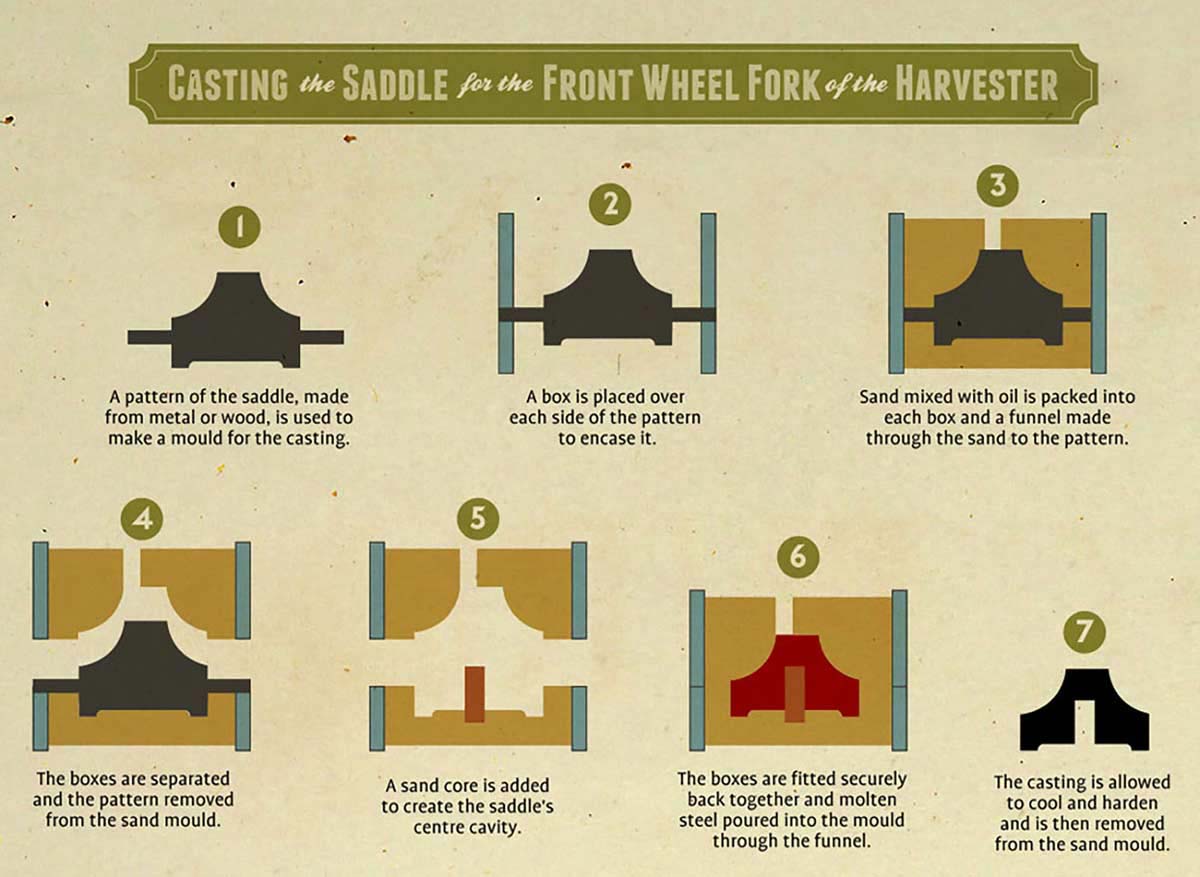

Casting the saddle for the front wheel fork of the harvester

- A pattern of the saddle, made from metal or wood, is used to make a mould for the casting.

- A box is placed over each side of the pattern to encase it.

- Sand mixed with oil is packed into each box and a funnel made through the sand to the pattern.

- The boxes are separated and the pattern removed from the sand mould.

- A sand core is added to create the saddle's centre cavity.

- The boxes are fitted securely back together and molten steel poured into the mould through the tunnel.

- The casting is allowed to cool and harden and is then removed from the sand mould.

Explore more on Tour of the Works