The old adage that ‘prevention is better than cure’ certainly holds true for collections. Protecting collections from damage is a vital part of the work that goes on behind the scenes at the National Museum of Australia.

Preventive conservation requires a continuous cycle of work involving expertise from the Museum’s Conservation, Registration and Facilities staff.

Providing stable storage conditions

All items in the Museum’s collection will deteriorate over time – this is a natural process but we can slow the rate of deterioration in many ways. Providing stable storage conditions appropriate to the types of materials in the collection is a first line of defence.

Not all objects require the same storage conditions, so it is important to understand the materials that make up each object in order to place them in their optimum storage environment. The Museum has a range of storage environments in its main building and off-site repositories and these have to be maintained and monitored.

Materials analysis

Given the different characteristics of different materials, it is important that conservators know what they are dealing with. This is where various analytical techniques come to the fore.

X-ray fluorescence

X-ray fluorescence (XRF) provides information about what elements are present in a material. It is a non-destructive technique for identifying metals and investigating the composition of materials such as paints, glass and ceramics.

When a test piece is bombarded with high-energy beams from an XRF machine, it gives out secondary X-rays that provide a unique ‘fingerprint’ of the elements making up the material.

X-ray fluorescence can also be used to check for the presence of hazardous elements such as mercury and arsenic. It can also be used to authenticate an object’s age or origin by looking at its composition.

Micro-fading

High-tech systems are also used to determine display periods for light sensitive objects. The Museum has done extensive work on micro-fading to better understanding the fading characteristics of objects.

This involves exposing objects to a very small pinpoint of infrared light. The results allow conservators to make more accurate predictions about the fading rate of objects if they are kept on display.

Collections 2010 series 14 May 2010

Risk management and light levels

Microscopes

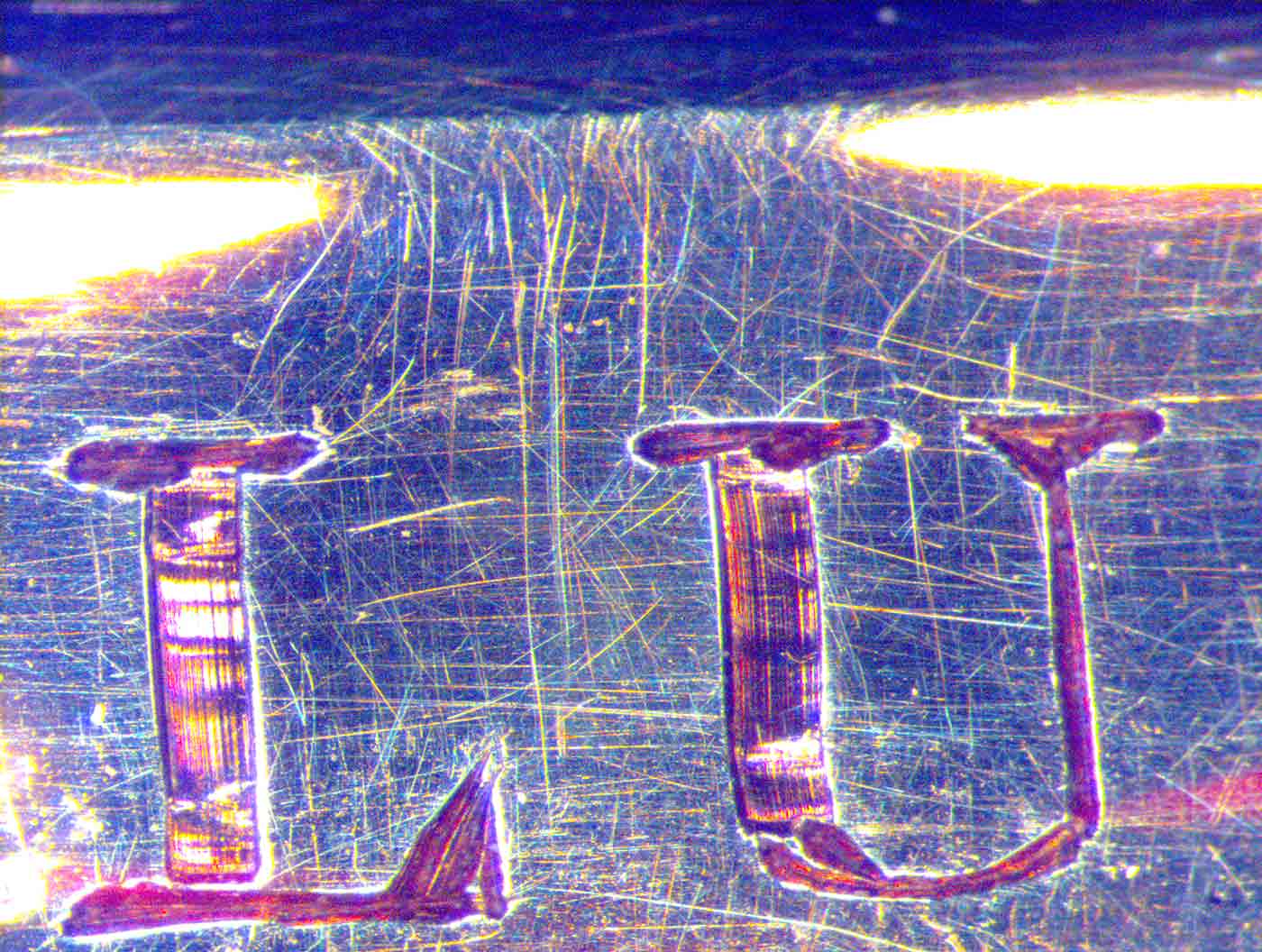

Microscopes are used by conservators to identify materials and examine the structure of objects. Lower levels of magnification help to clarify features that can be seen with the naked eye. Under higher magnification, the fibres of paper become visible. In the case of a medal awarded to explorer Ludwig Leichhardt by London’s Royal Geographical Society in 1847, surface characteristics not visible to the naked eye were revealed.

Examination of objects under higher magnification requires careful interpretation. Scratches on a metal surface, for example, might result from the manufacturing process or alternatively be evidence of damage from vigorous polishing.

Medal awarded to the explorer Ludwig Leichhardt by the Royal Geographical Society in 1847

At magnification x 10, details of the surface characteristics can be seen more clearly

Medal awarded to the explorer Ludwig Leichhardt by the Royal Geographical Society in 1847

At magnification x 60, scratches on the medal’s edge, become visible

Debugging the collection

A very important aspect of preventive conservation work is the detection and elimination of insect and rodent activity. All items that come into the Museum’s collection are inspected for pests and hazards, and all collection areas are continuously monitored.

If there is evidence of insect activity or of the outbreak of mould, the Museum’s preventive officer isolates the affected collection items and determines the appropriate treatment to eliminate the offending organisms, while keeping the collection items intact.

Bad bugs

Insects can cause devastating damage to collections if not controlled.

Carpet beetles, borers, silverfish and case-making clothes moths can make a meal of museum objects, especially those made from fabric, paper, wood, feathers and leather.

Conservators treat infested objects, but they prefer to practise prevention by creating conditions that discourage insects from coming into the Museum in the first place.

Anoxic treatment

To treat insect infestation, objects are snap-frozen at –21°C or placed in an oxygen-free, or anoxic, chamber. The oxygen inside the chamber is replaced with nitrogen, causing the insects to suffocate. Anoxic treatment is used on objects that could be damaged if frozen, such as feathers, bone and electrical equipment.